Technical capabilities

Comelf uses specialized equipment and technologies to ensure high-precision production, capable of meeting the complex requirements of its partners.

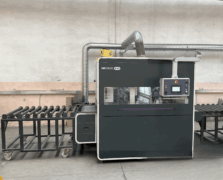

Cutting

Comelf has a complete range of cutting equipment, allowing the processing of metal sheets and profiles of various sizes and thicknesses:

- High-precision laser cutting, up to 20 mm thickness.

- Plasma cutting, up to 45 mm thickness.

- Oxy-fuel cutting for large thicknesses, up to 150 mm.

- Water jet cutting, up to 200 mm thickness, used for special materials.

- CNC saw with a cutting height of up to 800 mm, for efficient cutting of large-sized profiles.

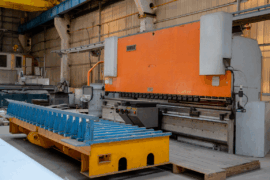

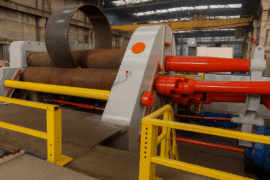

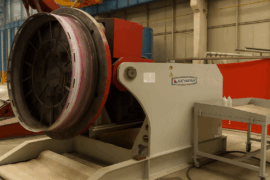

Cold Forming

Cold forming processes are carried out using high-performance equipment, ensuring precision in achieving the desired shapes:

- CNC bending machines with a force of up to 1000 tf and a working length of up to 7000 mm, for manufacturing complex components.

- CNC rolling machines for sheets up to 80 mm thick and 3500 mm wide, enabling the production of large cylinders and metal structures.

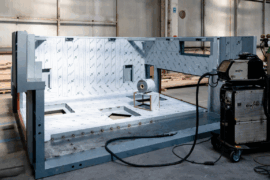

Welding

Comelf carries out welding operations using MIG/MAG and TIG processes, along with robotic welding systems for high-precision and high-productivity tasks.

The company holds various certifications for the execution of welded constructions, and welders and inspectors are authorized by specialized Romanian and international bodies. These accreditations serve as a guarantee of compliance for our clients.

The quality of welded joints is continuously monitored in our in-house laboratories, equipped with modern instruments for nondestructive and dimensional testing, ensuring that products meet all applicable technical and regulatory requirements.

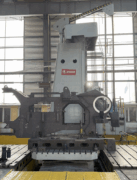

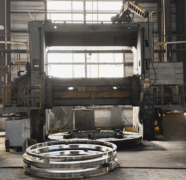

Machining

Our equipment enables the execution of complex machining operations on both small and large components:

- CNC lathes and milling machines for high-precision machining.

- CNC boring mill with an X-axis travel of up to 18,000 mm, allowing the processing of very long structures.

- CNC carousel lathes for parts with diameters up to 5,300 mm.

- CNC gantry milling machines for large components, ensuring tight tolerances and high-quality finishes.

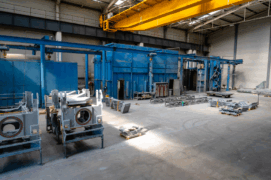

Heat Treatment

In order to provide the stability and the high performance of the welded structures, Comelf uses modern heat treatment equipment:

- Modular stress-relief ovens for maximum dimensions of 6500 × 6500 × 3600 mm or 13,000 × 3250 × 3600 mm.

This process guarantees the elimination of internal stress and enhances the durability of the products.

Surfaces protection

The final quality of products is ensured through comprehensive surface protection processes:

- Large-scale sandblasting booths for proper preparation of metal surfaces.

- Painting booths with maximum dimensions of 6,000 × 22,000 mm, including automated conveyor-based painting systems.

- Pickling and passivation booths for stainless steel products.

Final Assembly

Comelf provides final mounting activities for complex equipment, while integrating mechanical subassemblies with hydraulic systems, motors, electric installations and electronic equipment. This stage enables the company to deliver to its clients complete and functional products, tested in accordance with the technical requirements and the applicable quality standards.